Energy

Bundaberg Solar Farm

Project Overview

Location

Bundaberg, QLD

TYPE

Solar

Key Deliverables

100MW SOLAR FARM

SECTOR

Energy

Scope of Work

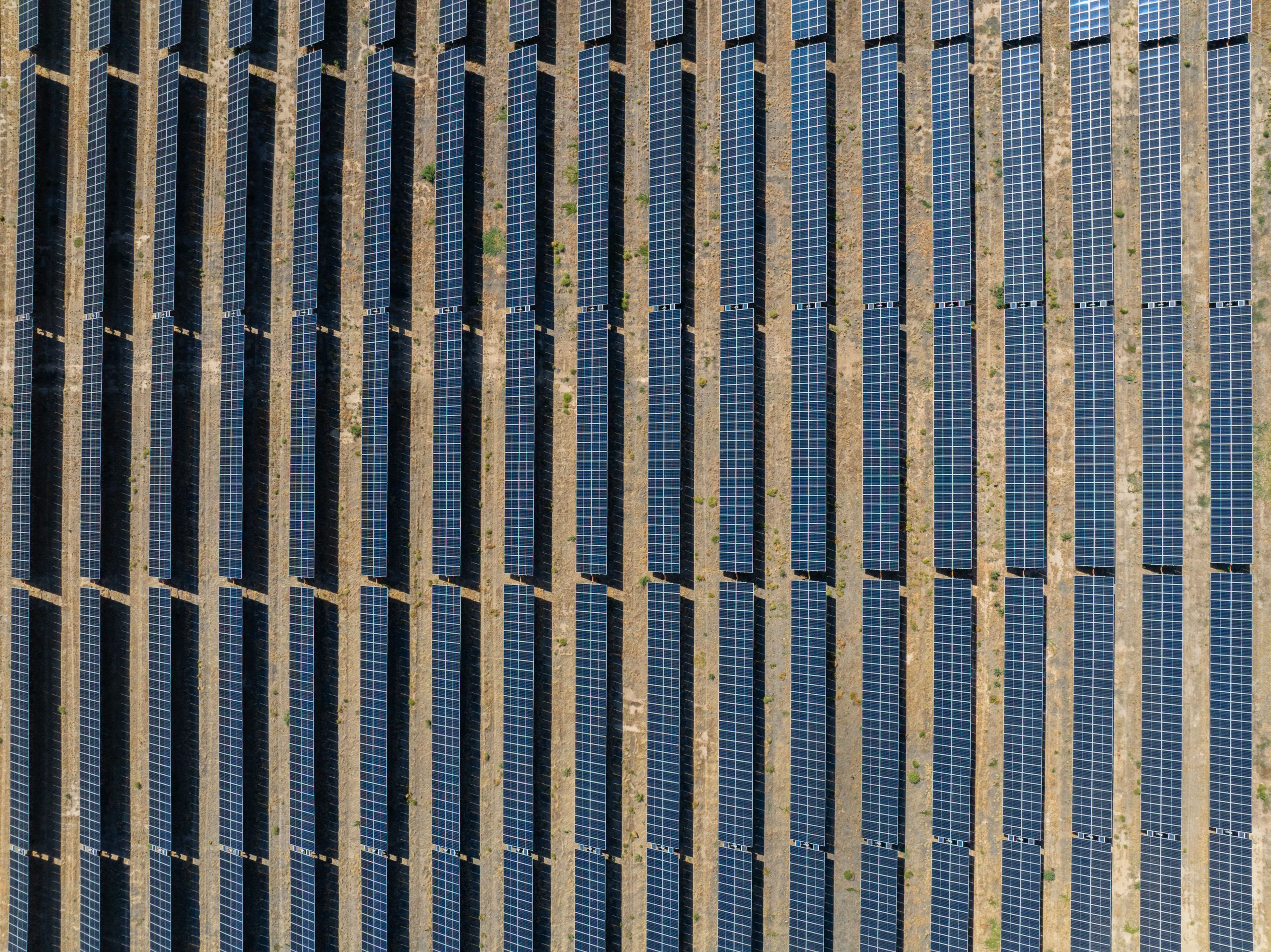

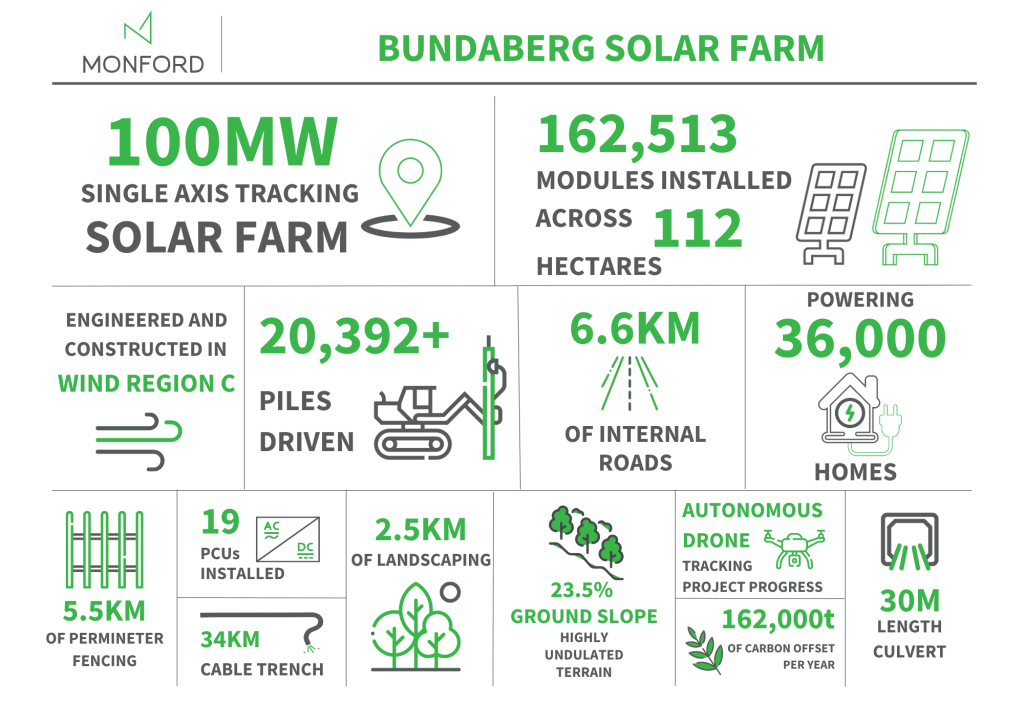

Located in Queensland’s Bundaberg region, approximately 360 kilometres north of Brisbane, the Bundaberg Solar Farm is a 100 MW single-axis tracking (SAT) solar photovoltaic project designed to generate clean energy for up to 25 years. Spread across 146 hectares, the farm comprises approximately 162,000 solar modules arranged in 2,319 rows, delivering a substantial renewable energy output to support Queensland’s decarbonisation efforts. This large-scale infrastructure project plays a key role in enhancing regional energy security while contributing to Australia’s renewable energy capacity.

As EPC contractor, Monford Group was responsible for the delivery of all civil, mechanical, and electrical works for the Bundaberg Solar Farm. Our scope included engineering, design, and partial procurement of key materials and components. We led the construction of all core infrastructure, including the installation of PV modules, single-axis tracking systems, cable routes, and electrical systems. Our team also delivered roadworks, drainage, and foundation works to support the structural and environmental integrity of the site. Commissioning activities were undertaken to ensure full operational readiness, with a focus on safety, performance, and quality assurance across every stage of delivery.

The Bundaberg Solar Farm plays a vital role in advancing Queensland’s clean energy future. With an expected annual output of 200 megawatt-hours, the farm generates enough renewable electricity to power approximately 36,000 homes each year. This clean energy production prevents around 104,000 tonnes of carbon dioxide emissions annually—equivalent to removing over 20,000 cars from the road.

Innovations and Challenges Overcome

The Bundaberg Solar Farm’s design and delivery methods were carefully tailored to overcome key challenges, including environmental considerations near sensitive waterways and variable weather conditions. To minimise impact on local habitats, the team implemented comprehensive environmental protection plans, including advanced water management systems and continuous monitoring to ensure regulatory compliance.

The weather variability, such as heavy rainfall and high winds, required a flexible approach, with phased scheduling and soil stabilisation measures to maintain site accessibility and prevent erosion. The design also featured a robust single-axis tracking system, engineered to withstand high-wind conditions, which reduced the need for extensive groundwork and accelerated installation.

Additionally, an autonomous drone system was used for real-time monitoring, providing valuable insights into site conditions and progress, ensuring high accuracy and enhanced safety throughout construction. These design and delivery innovations have resulted in a resilient, high-performing facility that will reliably provide clean energy for years to come

Delivery Highlights

Project Video

Project Gallery